1200 - 2000mm Width PE Air Bubble Film Machine With Back Unwinder Station

Product Details:

| Place of Origin: | China |

| Brand Name: | Vinot Brand |

| Certification: | CE certificate |

| Model Number: | DY - 1200 / DY - 1600 / DY - 2000 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1-3 set |

|---|---|

| Price: | The Best Price |

| Packaging Details: | Wooden Carton with Wooden Pallets |

| Delivery Time: | within 30 days after 30% payment in advance |

| Payment Terms: | T/T or L/C |

| Supply Ability: | 50-100 Set |

|

Detail Information |

|||

| Material: | HDPE / LDPE | Film Width: | 1200 - 2000mm |

|---|---|---|---|

| Extruder Electrical Power: | 18.5kw - 37kw | Bubble Specification: | 6 X 3.2mm 10 X 3.6mm 25 X10 Mm 30 X 10mm |

| Output: | 60 - 190kg / H | Gros Weight: | 3800kg - 6000kg |

| High Light: | air bubble film making machine,air bubble wrap machine |

||

Product Description

1200 - 2000mm Width PE Air Bubble Film Machine With Back Unwinder Station

High Speed Compound Air Bubble Film Machine

-- Wide In Width PE Air Bubble film Machine 2000mm

Model No. DYF-2000

![]()

Feature:

This air crew adopts the disposable shaping craft. It is our factory that draws domestic and international advanced technology extensively, through a large number of production practices in having ordinary equipment originally, develop, design, can produced polyethylene compound bubble (cushion) membrane in succession. Designs science, practical. Rational in structure of the machine.

![]()

Machine layout

![]()

Main Technical Parameter

| MODEL | DYF-2000 | DYF-2500 | DYF-3000 |

| SUITABLE RAW MATORIAL HDPE LDPE LLDPE | |||

| WIDTH OF PRODUCTION | 1900 | 2400 | 2900 |

| MAIN BUBBLE SPECIFICATION | φ6*3.2mm φ10*3.6mm φ25*10mm φ30*10mm | ||

| TOTAL INSTALLED POWER | 87kw | 102kw | 128kw |

| COVER DIMENSION(M) | 8*3.5*3.5 | 8*4*3.5 | 8*4.5*3.5 |

| OUTPUT | 100-160Kg/h | 120-190Kg/h | 150-230Kg/h |

| GROSS WEIGHT | 6T | 7T | 8.5T |

| EXTRUDER | |||

| SCREW DIAMETER(mm) | 65/65 | 70/70 | 75/75 |

| SCREW L/D | 30:1 | ||

| SCREW MATERIAL | SACM-65/38CRMOLA | ||

| CYLINDER MATERIAL | SACM-65/38CRMOLA | ||

| CYLINDER COOLING | 240 | 240 | 240 |

| DRIVING MOTOR(KW) | 18.5/18.5kw | 18.5/18.5kw | 22/22kw |

| TYPE OF DIE | |||

| DIE SIZE | 2000 | 2500 | 3000 |

| TEMPERTURE CONTROL | 7 | 7 | 7 |

| TAKE-UPUNIT | |||

| ROLLER WIDTH(mm) | 2000 | 2500 | 3000 |

| TAKE-UP SPEED(M/min) | 10-80 | 10-80 | 10-80 |

| TAKE-UP MOTOR(kw) | 2.2 | 2.2 | 2.2 |

| WINDING UNIT | |||

| SURFACE FRICTION/CENTER REWINDER | |||

| WINDING MOTOR(KW) | 2.2 | 2.2 | 2.2 |

| WINDING SPEED(M/min) | 10-80 | 10-80 | 10-80 |

|

Air Compressor Waste Recycling Online Automatic Roll Alternation Hydraulic Net Changer Air lift type winding additional part |

|||

Pictures:

auto loader

![]()

![]()

traction part

![]()

![]()

rewind part distribution box

![]()

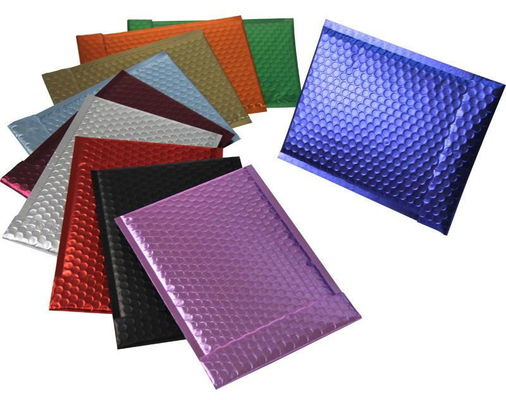

A bubble film pad is a membrane in the middle of the film containing an interlayer of bubble membrane. This composite membrane is low density polyethylene resin, the molten plastic extruder, in mold molding two layer film extrusion; one layer of membrane in vacuum roll by plastic film bubble shape, and another layer of composite membrane as a whole, the latter close to the opening with bubble film. This is the air cushion film composite membrane.

If the convex surface of the membrane is also combined with a layer of film, that is, the three layer composite air cushion film. Three layers of composite air cushion film, because of the bubble layer in the middle, the composite membrane is relatively light and elastic. It has the characteristics of moisture-proof, shockproof, sound insulation, beautiful, insect proof, mildew proof and low price.

According to the characteristics of the composite air cushion film, people use this film as a packaging material for instruments, instruments, ceramics and glassware.

![]()

![]()