Plastic Spliting Film Extruder Machine / Film Making Machine Vertical Type

Product Details:

| Place of Origin: | China |

| Brand Name: | Vinot Brand |

| Certification: | CE certificate |

| Model Number: | SJ - 65 / SJ - 85 / SJ - 95 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1-3 set |

|---|---|

| Price: | The Best Price |

| Packaging Details: | Wooden Carton with Wooden Pallets |

| Delivery Time: | within 30 days after 30% payment in advance |

| Payment Terms: | T/T or L/C |

| Supply Ability: | 50-100 Set |

|

Detail Information |

|||

| L / D Ratio: | 28 : 1 | Output: | 40 - 130kg / H |

|---|---|---|---|

| Speed Of Screw: | 30 - 80 | Thickness Of Tape: | 0.015 - 0.07mm |

| Screw Diameter: | 65mm / 85mm / 95mm | Width Of Oven: | 900 - 1300mm |

| High Light: | plastic rope machine,plastic rope manufacturing machine |

||

Product Description

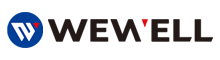

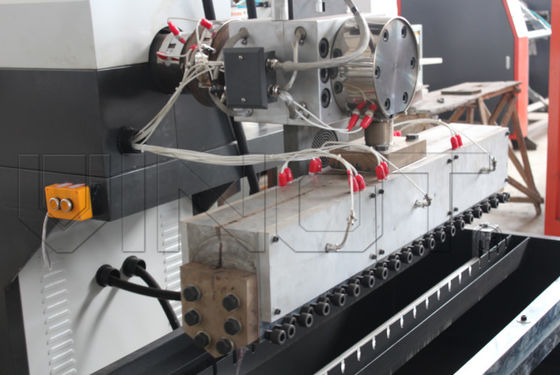

Plastic Spliting Film Extruder Machine / Film Making Machine Vertical Type

Vertical Type Plastic Spliting Film Making Machine

![]()

![]()

Optional Device:

1. Auto loader

2. Hydraulic continuous screen changer

3. Centralized winding machine

4. Spearate winding machine

![]()

Feature:

The machine adopts domestic and international advanced technology,through a large number of production practice,development,innovation.The rewinder adopts single torque motor.The raw material is PP.The machine produce various slitting film that used for packing things. When the machine with the red ball making machine,it can produce various model,specification line ball.

![]()

Main Specification:

|

![]()

Application

(1) Automatic controlling system, the entire production line adopts new control system, delta frequency and advanced PLC, more stable and high efficiency.

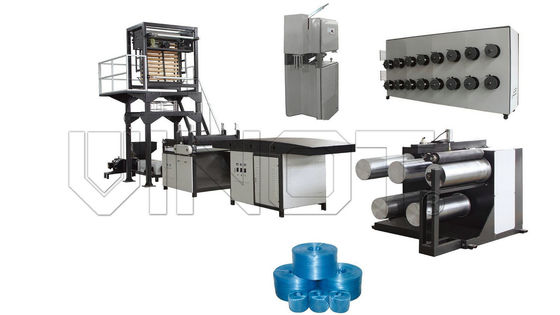

(2) Single screw extruder: Screw adopts Nitriding process , could bear high temperature ,more durabile, and good plasticizing quality. Machine with pressure sensor and metering pump to control the f pressure and the flow. It’s convenient to change different spinneret size to make different dia of yarn.

(3) Cooling system: steady temperature ensure the twine soft and shiny with good feature.

(4) NO 1 and NO 2 stretching: ss material is to make the yarn good stretching, steady speed

(5) Heating system: half of heating tube will stop after temperature getting to the settled data, this could reduce the cost , low consumption.

(6) Winder has separate motor to control each winding head, for monofilament, there exist several kinds of winding type.

Details Picture :

![]()

![]()

Packaging & Shipping

1. Port: Ningbo

2. Packaging details: With stretch film and bubble film package outside

3. Delivery detail: Within 30 work days after receiving the deposit payment